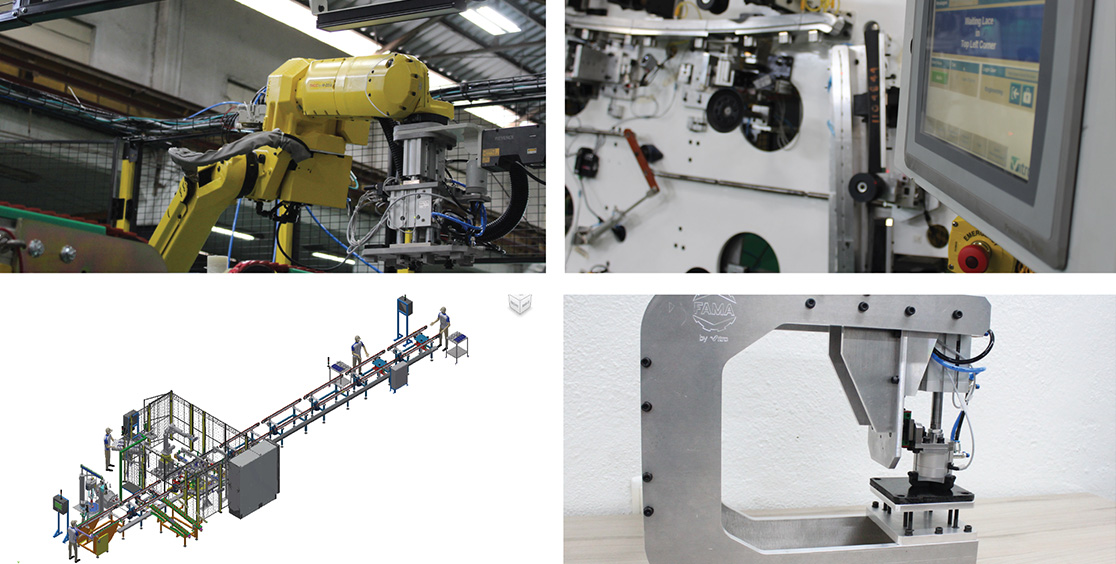

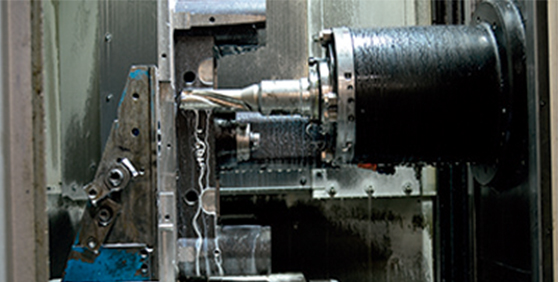

FAMA, born in 1943 as Vitro’s subsidiary for in-house machinery manufacturing, has a proven track record of creating forward and innovative industrial technology. With over 75 years of experience to stand on, FAMA now looks ahead as it extends into other industries to offer machine manufacturing, equipment and bespoke solutions. This in order to make the most of our capabilities.